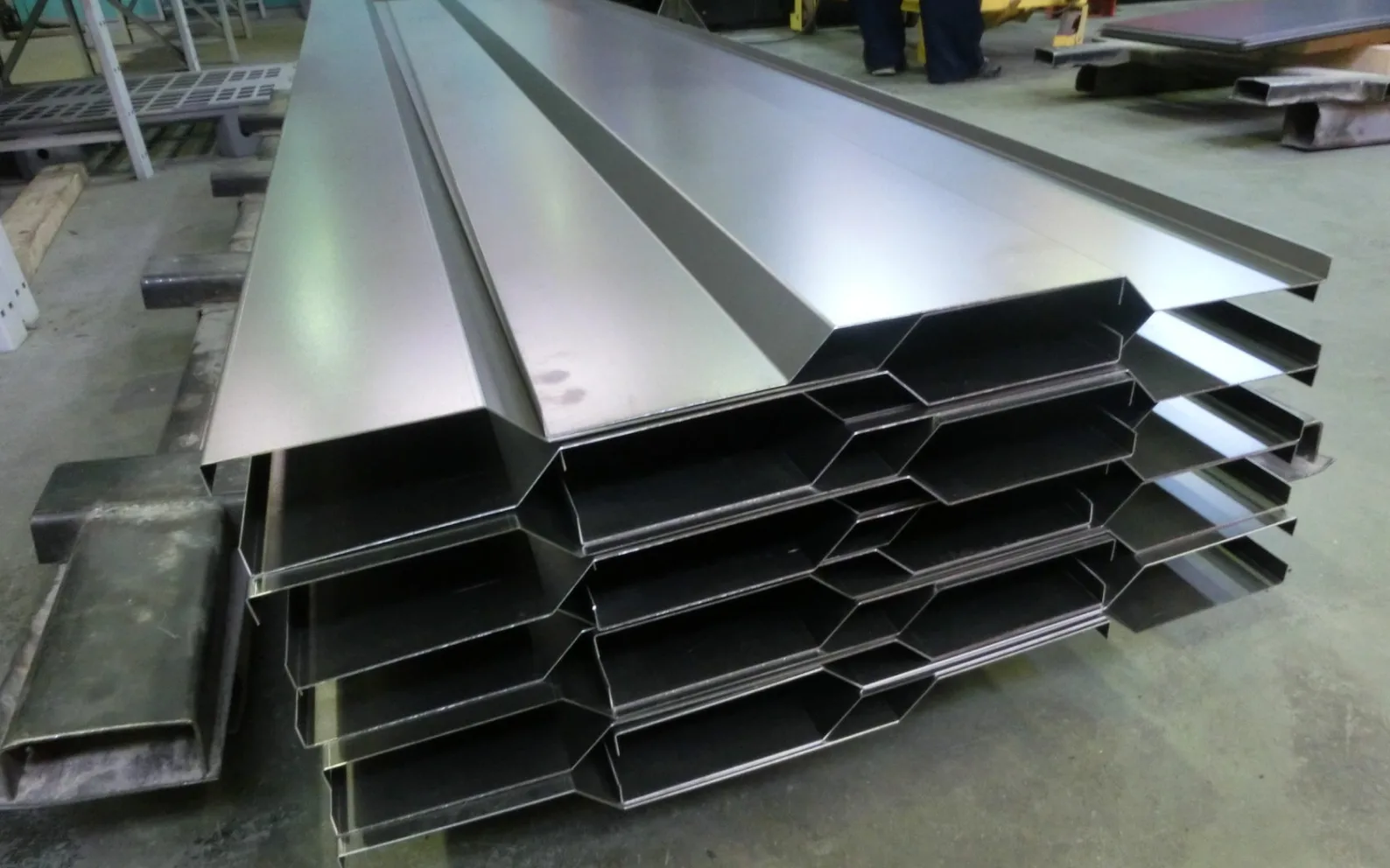

Bending & Punching

Sheet metal bending is a process used to shape flat sheets of metal into specific angles or curves by applying force through various bending techniques. Our sheet metal bending is performed by using a CNC bending technique with 5 axes, manufactured by Amada. The working area of the machine is 3000 mm, while its bending force is 130 tons.Sheet metal bending can be performed on various metals, including:

- Steel (carbon steel, mild steel)

- Stainless Steel (for corrosion resistance)

- Aluminum (lightweight, corrosion-resistant)

- Copper (conductive and corrosion-resistant)

- Brass (for decorative or high-performance uses)

Punching

Sheet metal punching is a metalworking process in which a punch and die are used to create holes, slots, or other shapes in a sheet of metal.

The main characteristics that define sheet metal punching are:

- CNC program which enables quick response to changes in customer needs

- Up to 58 punching tools (per program), which can be complemented by multi-digit tools (multi-tools)

- Sheet metal punching with accuracy of up to 0.1 mm

- Processing of material in plates for dimensions of up to 1500x3000mm

- Processing of material with the thickness of up to of 3mm, for stainless steel up to 2mm

Our Products